The thermal pad is often derided, but it has advantages. It isn't messy, it's pre-applied and it's evenly distributed across the surface, which is why manufacturers like it for their retail heatsinks. It's also less likely to creep in the long term than cheaper pastes.

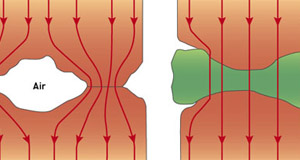

However, a thermal pad's thermal conductivity usually isn't as good as that of proper TIM, and the pads only work under constant pressure from the heatsink retention clips. If these don't provide enough pressure, the pad is useless. In addition, there can be long-term problems; as the heatsink base and CPU grow or shrink due to heat, the pads don't always keep up, and air pockets can be introduced. Read more at Bit Tech.