How do Distillation Towers work?

Posted on Friday, September 27 2019 @ 8:26 CEST by Thomas De Maesschalck

The goal of this guide is to help you understand by simple means that how this process works and do whatever it is that you intend to do through simple and direct instructions.

We will discuss different type of distillation along their working principle and examples

You will be acknowledged with the comparison and advantages of each method so you can select your desire one as per you need for your industrial application

How this works?

A process of boiling a liquid and condensing it via vapors in a separate column or container form for the separation of the liquid mixture.

It's a separation technique you can use for either increase the concentration of a selective part within the mixture or get(almost) pure parts from the mixture.

The method of distillation works due to the difference of the boiling points of each part or mixture in the liquid mixture by forcing one in every one of them into a volatilized state in order to separate.

It is vital to notice that distillation isn't a chemical process however it is often thought of as a physical separation process.

Associated illustration defining the laboratory setup that's usually used to process this method is shown above.

Now we will talk about different methods and their working principles.

1. Simple Distillation

It is employed for the separation of a dissolved solvent with a solution. Real case common using practical example is drinking water being distilled from salt solutions resources.

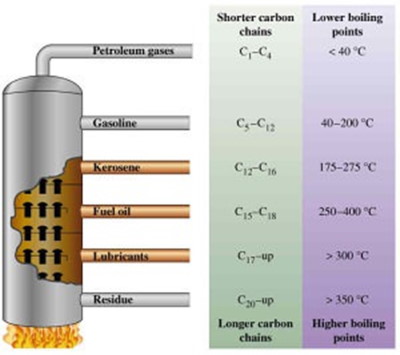

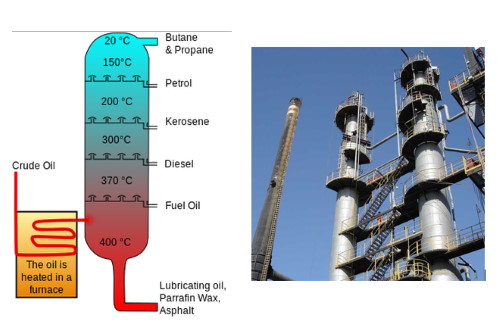

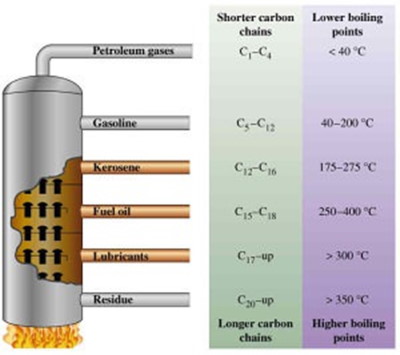

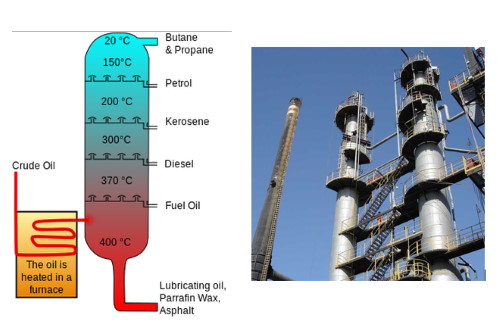

2. Fractional distillation Towers and Their Working

Fractional distillation towers are employed to separate totally different liquids from a mix of liquids.

It's helpful for separating fermentation alcohol from a mixture of ethanol and water, and for separating totally different fractions from oil.

Fractional distillation process works as a result of the various liquids have different boiling points.

Once the mixture of liquids is heated in a heating zone, part of lower boiling points evaporates and vapors rise through a column that is hot at the underside, and cold at the highest

Vapors condense once they reach a component of the column that's below the temperature of their boiling point

There are 2 ways in which of getting totally different liquids from the column:

You can collect totally different liquids from different components of the column. The substance with all-time low boiling point is collected at the highest of the column and vice versa when you move downwards

You can continue to heat the mixture to extend the temperatures within the column. The substance with all-time low boiling purpose is collected initially.

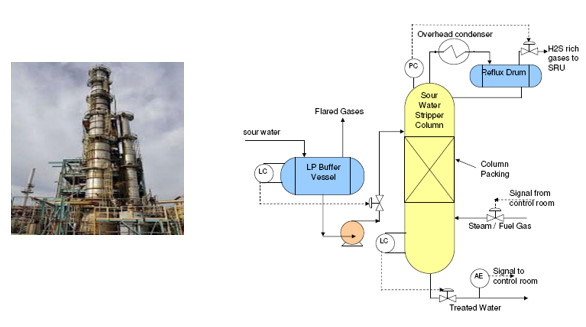

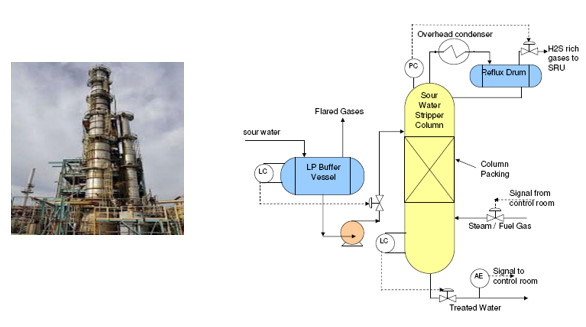

3. Steam Distillation Towers

These towers are employed for the purification of such mixtures, within which the elements are temperature sensitive; for instance, organic substances.

Steam enters by heating water, that permits the organic substances to boil at a lower temperature.

That’s how such compounds are separated before they decompose.

The vapors are collected and condensed within the same means as different distillation varieties.

The resultant liquid consists of 2 phases, water, and compound, that is then sublimated by simple distillation method.

This method is applied on a big scale separation of perfumes and essential.

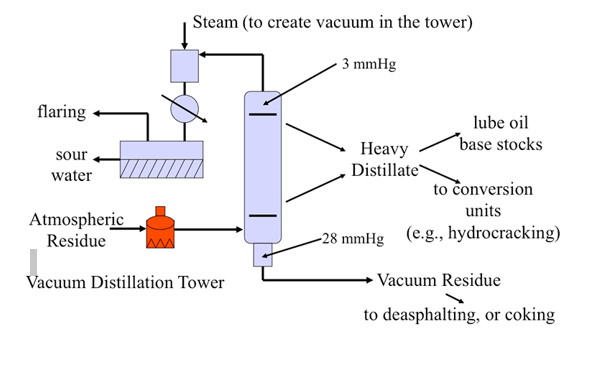

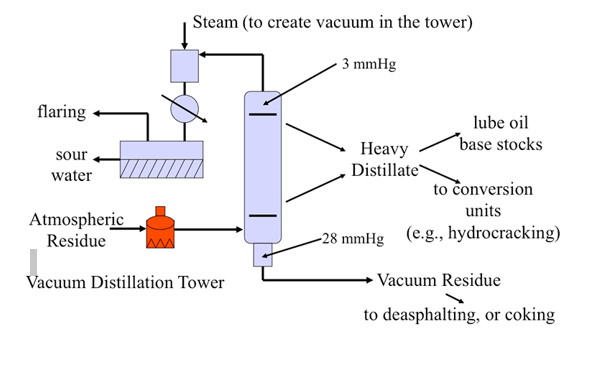

4. Vacuum Distillation Towers

They employed to separate parts that have higher boiling points that require high heat or energy input.

Lowering the pressure of the equipment conjointly lowers boiling points.

Otherwise, the method is other distillation methods.

Vacuum distillation process is especially helpful once the conventional boiling purpose surpass the decomposing temperature of a compound.

Packaging Use in Distillation Towers:

Random packing may be a structure created of specifically designed components which are suitable for processing plants.

It has many uses such a purification and waste water treatment, absorption of assorted gases and liquids, volatilized and filtration.

The categories of ordinarily used packing materials are random packing, pall rings and raschig ring.

Random packing devices used in heat and mass transfer applications in distillation tower and considered as a heart of the tower.

Packing material is employed rather than trays to boost separation in columns. Packing gives the benefit of lowering the pressure drop within the tower (while comparing to trays or plate), that is useful whereas operative beneath vacuum.

The primary purpose of them is to make contact of vapor or liquid to them as long as possible to transfer the heat.

As a design manufactures, we have a tendency to prepare and choose the suitable packing that has the foremost economical balance capability and potency.

The smaller and compact size of the packing goes, the higher the efficiency but at a worth of lower capability and higher price.

Raschig rings are the oldest forms of random packing, which we have a tendency to still use commonly.

They have relatively low capacity, efficiency and high costs (in metallic structure).

we have also a tendency to limit corrosive utilization applications where the material of construction is ceramic or carbon/graphite.

Gustawater offer a large variety of Packing materials such as of each category to fulfill your desire requirements of distillation applications.

Applications

Distillation towers plays a crucial role in separation method.

Several chemical process plants incorporate these towers.

Oil stabilization is a crucial style of distillation that reduces the pressure level of petroleum, facultative safe storage and transportation.

Distillation towers are additionally used on associate degree industrial scale to purify the liquid product obtained from chemical synthesis.

Distillation towers are employed for several industrial processes, like the assembly of gas, water, paraffin, kerosene, and plenty of different liquids. Gases are also liquefied and separated like N, O2,

Conclusion

Distillation is a method of boiling and condensing a liquid from mixture and distillation towers work on that principle.

We have mentioned 4 different general types of distillation towers i.e Simple distillation, Fractional distillation, Steam distillation, Vacuum distillation towers.

Common applications of uses of distillation are purification, desalinization, petroleum refinement, and creating liquefied gases from the air.

Humans are using distillation for a minimum of 3000 before Christ within the Indus depression.

Gustawater offer a large variety of packing material for any type of distillation column as per buyer requirements.